In many situations, particularly when testing protective relays, a large number of simulation cases must be run and evaluated (e.g. point on wave switching, varying fault type and fault impedance, etc.). Therefore, an automated multi-run or “batch” operating mode that essentially eliminates the need for user intervention is required. The RTDS Simulator provides the Automated Batch Mode capability for running cases, analyzing results, and customizing report generation with limited user interaction.

The RTDS Simulator’s automated operation software is incorporated into RSCAD RunTime and can be divided into three major sections: the record/replay facility, the script file facility, and pre-processor components. Together, these features make it possible to automatically execute a complex test sequence and provide the results in a user-customized report.

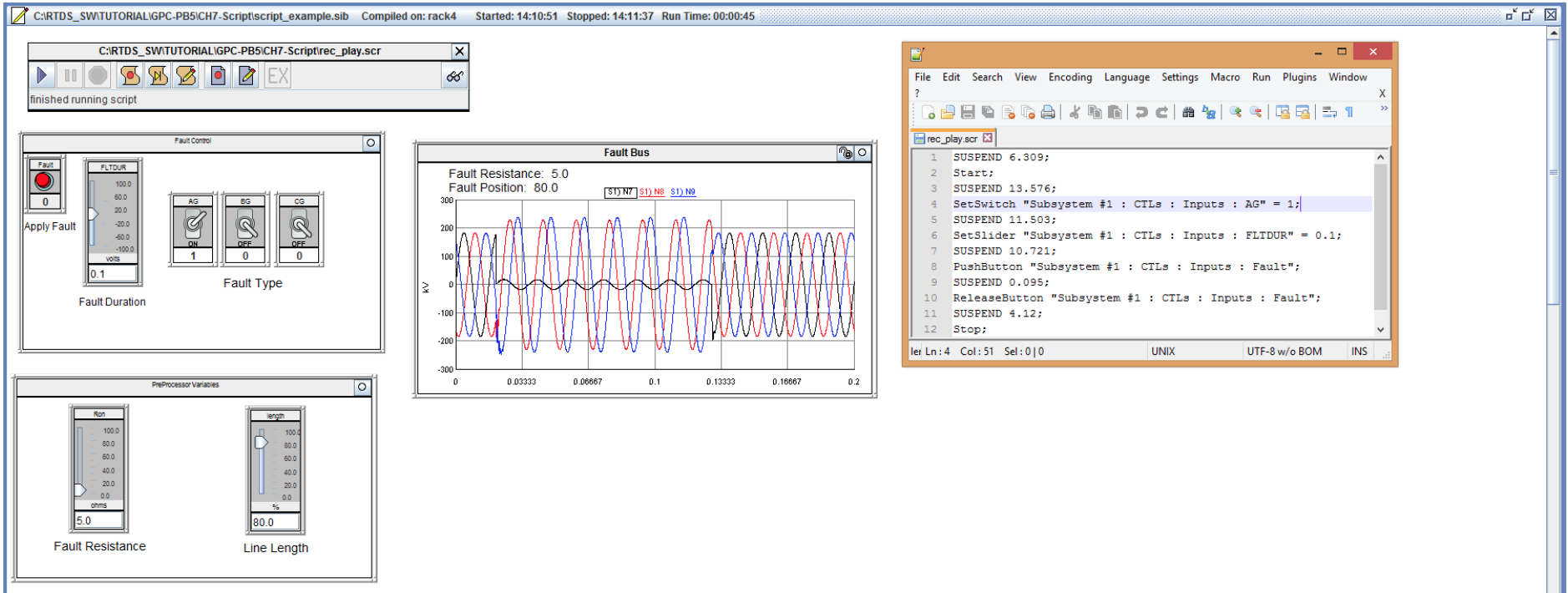

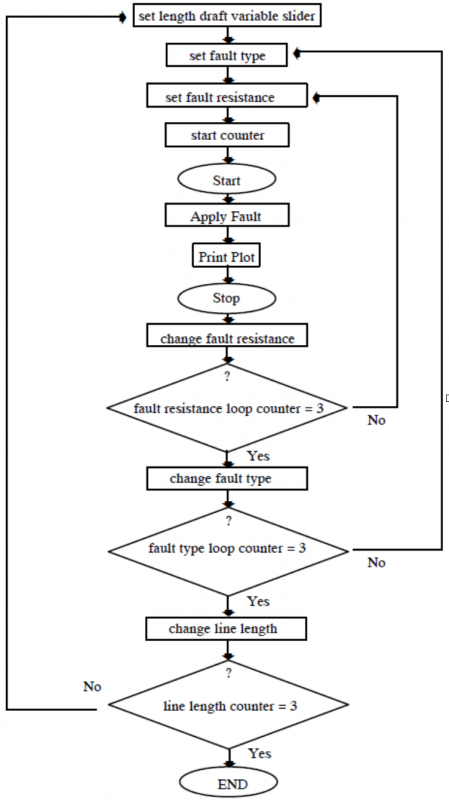

At the bottom of this page is a sample flow chart of an automated simulation that might be executed using the following process, as well as a screenshot of what the automation facilities look like in the RunTime module.

Record and Replay Facility

The easiest way for the user to begin automating simulator operation is via the record/replay feature.

The record feature allows the user to store manually initiated events – such as the downloading of simulation cases, the adjustment of system set points, the application of faults, the capture of output waveforms, etc. – to a macro.

Once a series of actions has been recorded, the replay feature can be used to repeat those actions many times without the need for further interaction by the user. Optionally, the text file containing the recorded commands can be edited to change the sequence or remove unwanted commands (see “Script File Facility” below).

The record and replay features are particularly useful when a large, complex simulation case (e.g. a case containing many synchronous machines) is being brought to its steady-state condition. Each time the case is started, the script file can be executed to ensure same start-up procedure is applied and steady-state conditions are achieved in a consistent, stable manner. Once in steady state, the transients that are to be studied can be applied.

Script File Facility

When it comes to creating entire test sequences and customized reporting, the full power of the script file feature is used. This feature is essentially an extension of the record and replay facility through which the user can introduce additional functions or events to pre-record operations.

The record feature described above automatically generates and stores a script file. After recording, the script file may also be modified to introduce refinements or to create a more complex script sequence. For example, the user may introduce result analysis functions such as trip time measurements, FFTs, max./min. searches, logical operations, etc. and have the results of these functions displayed graphically, stored in separately defined output files, or printed. Additionally, conditional/adaptive looping via if, for and while statements may also be added to the script file. In this manner, the user can completely customize test sequences and the reporting of results.

Essentially the script file is a “C” program that includes special simulator commands (ie. start, stop, push button, etc.). Because of this, it is very straightforward and easy to learn for anyone familiar with C-type programming – even for those with relatively little programming experience.

Pre-Processor Components

The RTDS Simulator pre-processor components provide a method to automatically re-compile simulation cases when certain types of circuit variables are changed. Similar to record/replay and script file management, all operations relating to the pre-processor are accomplished through the RSCAD RunTime.

Modifying the value of a fault impedance represents a typical situation in which the pre-processor is required and utilized. In this case, the user may specify from either RunTime or from a script file that the fault impedance at a particular point should vary between a minimum and maximum value. Since changes in the fault impedance affect the overall system admittance matrix, new matrices must be created. The RTDS software recognizes the requested change and takes the appropriate action. The next time the simulation is run, either manually or automatically, the new fault impedance will be available.

All parameters of the RSCAD Draft case can be modified by substituting a parameter with a special Draft variable.

Flow chart of potential automation sequence:

Screenshot of the automation facilities in RunTime: