User profile: A service provider supporting critical electrical infrastructure worldwide

Schweitzer Engineering Laboratories, Inc. (SEL) invents, designs, and builds digital products and systems that protect power grids around the world. Their SEL Engineering Services department provides complete protection and automation solutions for customers worldwide. Since 2001, SEL Engineering Services has used the RTDS Simulator to support their work, and today operates the largest commercially-available real time power system simulator in the world with dozens of experienced engineers. This technology allows for customer-specific application testing and Factory Acceptance Testing of SEL’s turn key solutions.

The RTDS Simulator is used to represent the power system of interest, which is then connected to SEL’s protection, automation, and control devices in a closed-loop interface. In this way, the proposed solution can be exposed to a wide variety of operating scenarios and contingency conditions, providing performance assurance to both SEL Engineering Services and the client.

Project focus: The first high-voltage line protected with travelling wave relays

The Public Service Company of New Mexico (PNM) was building an interconnection on a series-compensated 345 kV line. Splitting the line resulted in heavy overcompensation of the first portion, leading to improper coordination and misoperation of protection schemes.

PNM engaged SEL’s Engineering Services team to develop a solution. The original plan was to use a line current differential scheme for principal protection, with SEL’s cutting edge travelling wave protection relay—the SEL-T400L—in monitoring mode. Acceptance testing with the RTDS Simulator changed the plan.

When SEL demonstrated the operation of the SEL-T400L with the RTDS Simulator, the test results gave the customer the confidence to deploy the relay with direct tripping.

The testing tool: Special models and considerations for travelling wave protection

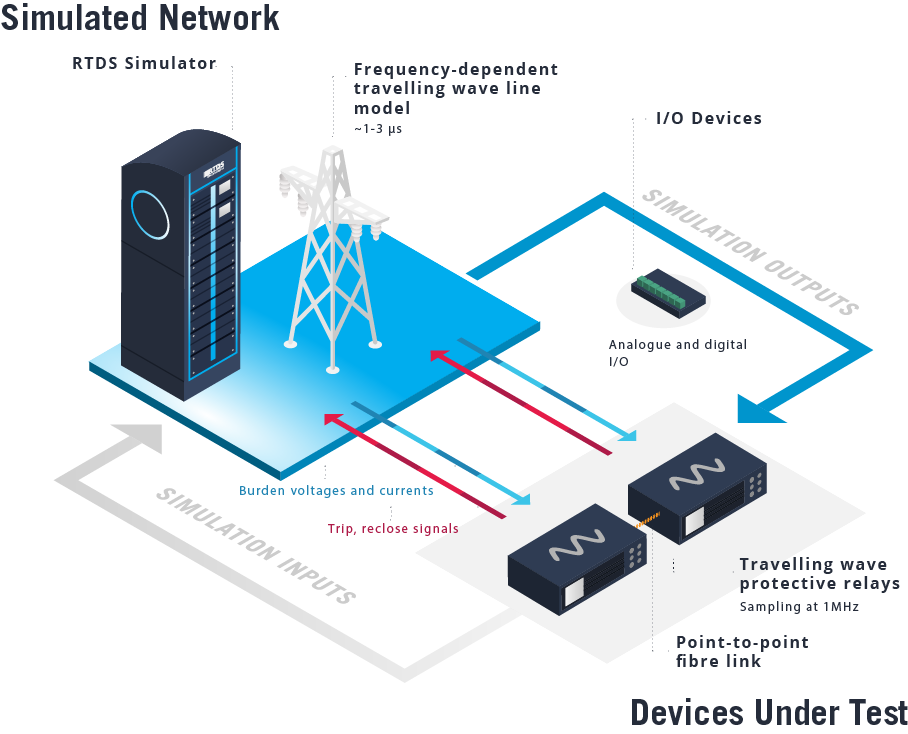

The RTDS Simulator uses dedicated parallel processing hardware to represent power systems in real time. Signals can be sent into and out of the simulated environment to form a closed-loop interface with external hardware.

To accurately test a relay based on travelling wave protection principles, Bergeron transmission line models operating at the typical simulation timestep of 25 to 50 µs are not sufficient as they do not model the attenuation of the travelling wave.

RTDS Technologies has developed frequency-dependent line models running at a timestep of ~1-3 µs, making the RTDS Simulator the only tool with the accuracy necessary to test travelling wave relays in a closed loop.

Outcomes and looking ahead: Inventing the future power system together

Closed-loop testing of the SEL-T400L relays with the simulated PNM power system revealed unprecedented results:

- 600 µs operation time (for the travelling-wave differential element, for a midline single-phase fault

- Fault location reported to within 0.02 miles on a 33.1 mile line

Acceptance testing with the RTDS Simulator in the SEL Engineering Services facility was sufficient to give the customer the confidence to deploy the

SEL-T400L relays with direct tripping, making them the first utility in the world to do so. Shorter clearing times and lower exposure to fault currents will decrease power system equipment degradation and lower life cycle costs. Super-accurate travelling wave fault location will also save PNM hours of extensive patrolling.

As our power system continues to evolve, SEL will be at the forefront of protection and control development. Alongside them, real time simulation will continue to play a role in building the confidence to deploy novel systems.